Factory inspection

On November 20, 2025, Guangxi Pinglu Canal Construction Co., Ltd. held a factory acceptance meeting in Changzhou for the upper and lower gates and hydraulic gate hoists of the working valves of the Pinglu Canal Madao Hub (Right Line) navigation lock.

The meeting was held at the Hengli Hydraulic Co., Ltd. plant , bringing together representatives from the owner, design unit, supervision unit, inspection unit, installation unit, manufacturing unit, and control unit, and successfully completed the acceptance of this batch of equipment.

Century-old project drives waterways

The Pinglu Canal is a strategic project serving the national "Belt and Road" initiative and the new development pattern. It is 134.2 kilometers long and, upon completion, will be navigable by 5,000-ton vessels . It will open up the shortest, most economical, and most convenient route to ASEAN for Guangxi and Southwest China. Goods from Southwest China will be able to reach the sea via the Pinglu Canal, shortening the inland waterway journey by more than 560 kilometers compared to shipping via Guangzhou Port, and logistics costs are expected to decrease by approximately 30%.

As the primary hub and key, challenging control project of the Pinglu Canal , the Madao Hub is the "first gateway" from the Xijiang River into the canal.

The hydraulic gates and working valves of the Madao Hub (Right Line) navigation lock , which were inspected and accepted this time, are fully used for gate opening and closing and water level regulation. They are the core equipment to ensure the normal operation of the navigation lock and realize the navigation function of the canal.

Dedicated to Breakthroughs and Building the Nation's Lifeline

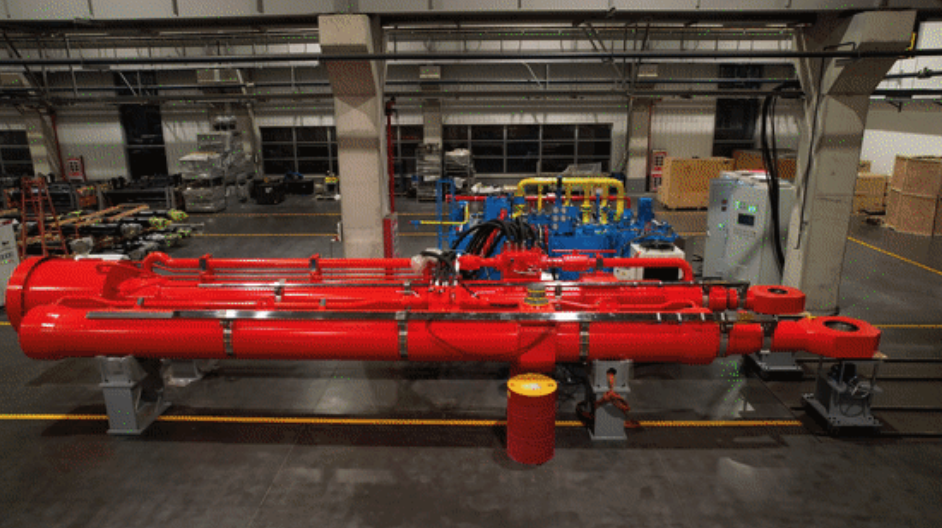

For hydraulic gate hoists used in various applications such as miter gates in navigation locks, working valves in water conveyance corridors, and working valves in water-saving pools, Hengli Hydraulics has precisely matched different solutions, delivering a total of 20 hydraulic cylinder assemblies and 12 hydraulic pump stations . Among them, the miter gate hydraulic gate hoist adopts high-flow proportional variable regulation technology to ensure precise positioning of the miter gate; the hydraulic gate hoists for water conveyance corridor working valves and water-saving pools employ new throttling and buffering technology to ensure stable operation of the hydraulic cylinders and achieve efficient water level regulation.

The acceptance team rigorously conducted a comprehensive inspection of the gate hoist equipment in accordance with relevant specifications and standards, through document verification, on-site testing, and functional verification. Ultimately, the test results met the requirements of the contract, specifications, and Pinglu engineering standards, and the equipment was approved for shipment . Hengli Hydraulic products provide a solid guarantee for this landmark project with their superior performance.

Sharpening our swords and overcoming difficulties, we are determined to succeed.

At the outset of the project, Hengli Hydraulics faced two major challenges: first, the equipment needed to withstand long-term humid environments, which placed extremely high demands on the materials and surface treatment processes of the hydraulic cylinder piston rods ; second, the precision requirements for the coordinated control of multiple hydraulic cylinders were stringent, with a synchronization error of less than 15mm to ensure gate safety.

Hengli Hydraulics has provided a better solution to overcome the above problems.

At the initial design stage, technicians optimized the structure and conducted simulation verification of the hydraulic cylinder based on hydraulic standards to ensure the structural stability of the hydraulic cylinder under high pressure and long stroke operation.

Hengli Hydraulics, relying on internationally advanced surface treatment technology and a professional spraying R&D team, and equipped with advanced production equipment, precisely solves process challenges such as coating wear, oxidation, and corrosion, achieving the special protection requirements of applications. Furthermore, by combining HVOF supersonic spraying and plasma spraying technologies , it significantly improves corrosion resistance and wear resistance, fully capable of handling the humid environment of canals.

(Demonstration of supersonic spraying technology)

For multi-cylinder operation, we use a proportional variable pump to control the operating speed , employing a "slow-fast-slow" speed-changing mode to achieve high-precision synchronous control. This is further enhanced by ceramic rod sensors and external static magnetic grating displacement sensors to monitor the hydraulic cylinder position in real time . Precise PLC control ensures that the synchronization error between the left and right bank equipment is ≤15mm.

Conclusion

The successful acceptance marks Hengli Hydraulics' official entry into the high-end water conservancy equipment field. Taking the Pinglu Canal, a landmark project of the century, as a milestone, Hengli Hydraulics has successfully transformed its technological advantages in ultra-high load, high-precision control, and environmental adaptability into providing a stable and reliable "hydraulic heart" for large-scale water conservancy projects, and will continue to promote the high-quality development of the national water conservancy cause with "Hengli Power".